We at Primostar have been working with waterproofing solutions for over twenty years. We sell waterproofing materials in reinforced concrete structures designed to make parts of buildings and structures below ground level waterproof. We also install these materials.

Over the years, we have seen how the market has moved from using old classic waterproofing materials, or the “black tank” method, to a new, modern version, the “white tank” method.

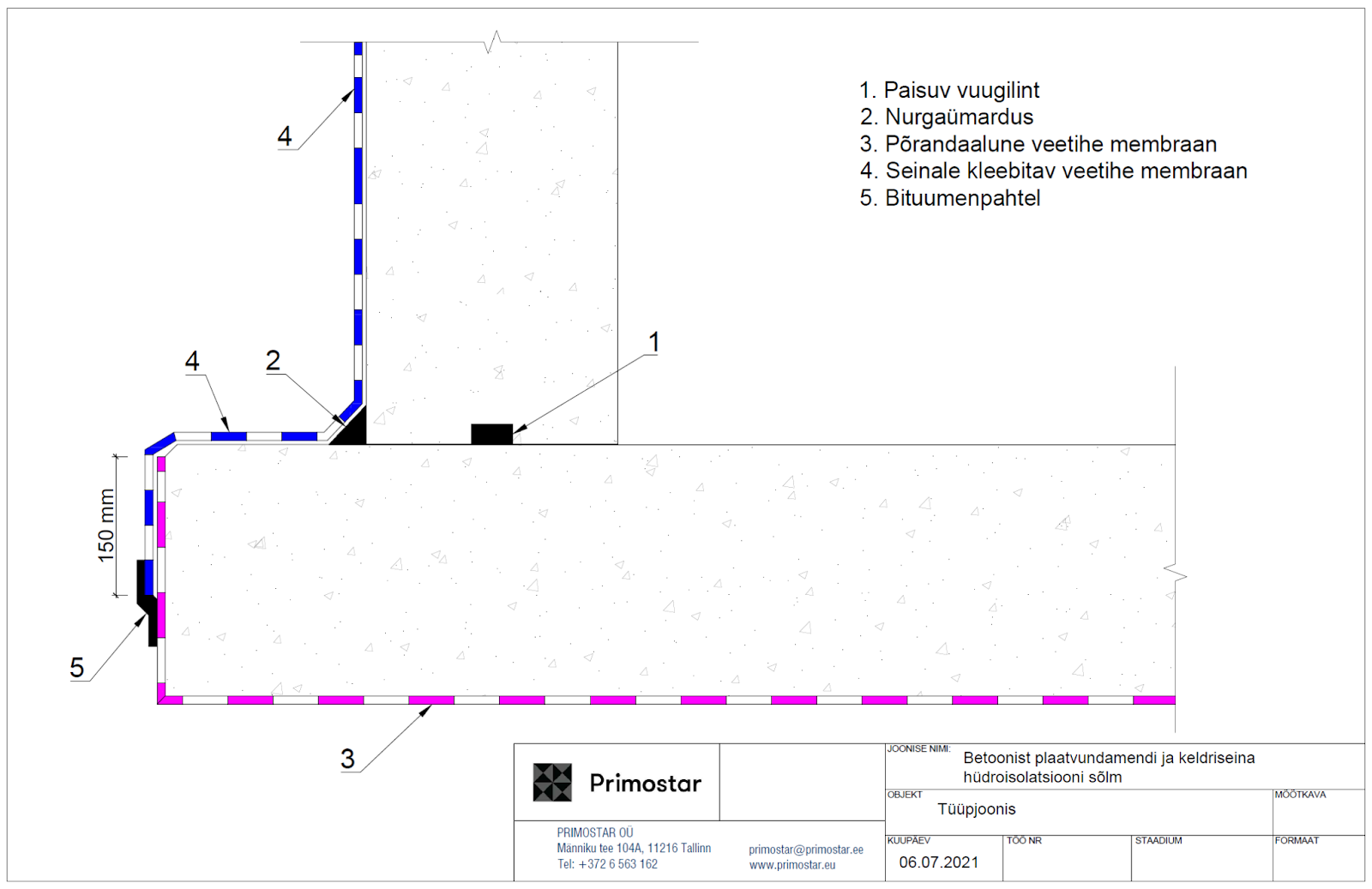

Figure 1

“black tank” method

“white tank” method

Figure 1: Concrete slab foundation and basement wall waterproofing joint. Two watertight membranes are used for this “black tank” method. Waterproofing of concrete structures

A “black tank” is a waterproofing system in which the underground surface of a building is pre-insulated with a watertight membrane before the concrete is poured. After casting the structure’s concrete, the walls and inverted roofs are waterproofed with an adhesive watertight membrane.

A “white tank” is a waterproofing system that uses concrete mixtures with a waterproof admixture. In addition, when using the “white tub” method, water resistance must be ensured in all work joints, for example, by using WPM construction joint profiles.

The "black tank" solution for membrane waterproofing has higher material and labor costs than the "white tank" method.

"White tank" method

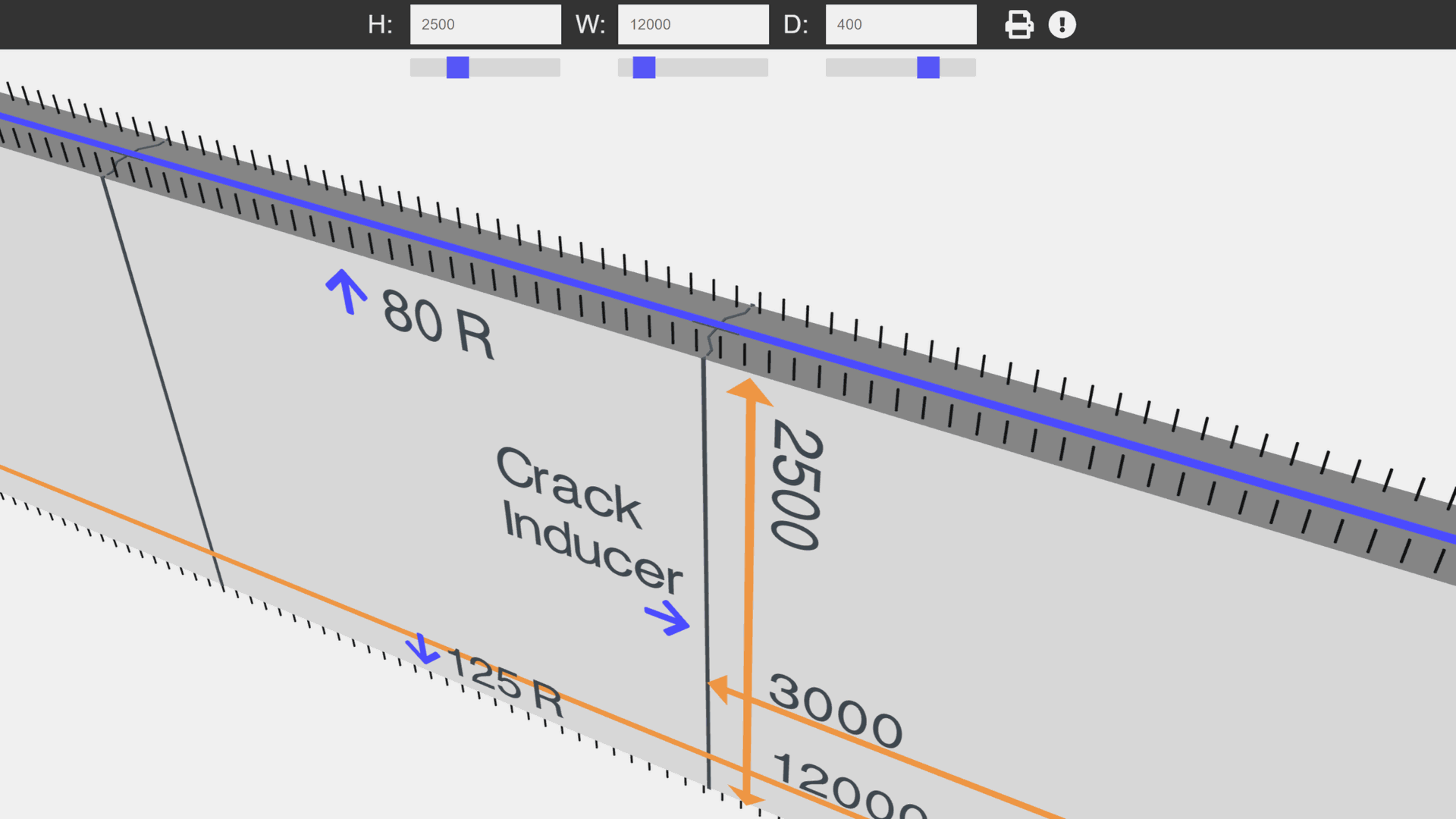

The "white tank" method consists of three parts, the first of which is the crystalline admixture that is added to the concrete mixture in the concrete assembly. Secondly, construction joint profiles are added to concrete joints before casting. And thirdly, we can use the Crack Inducer Profile to pour larger volumes of concrete at once.

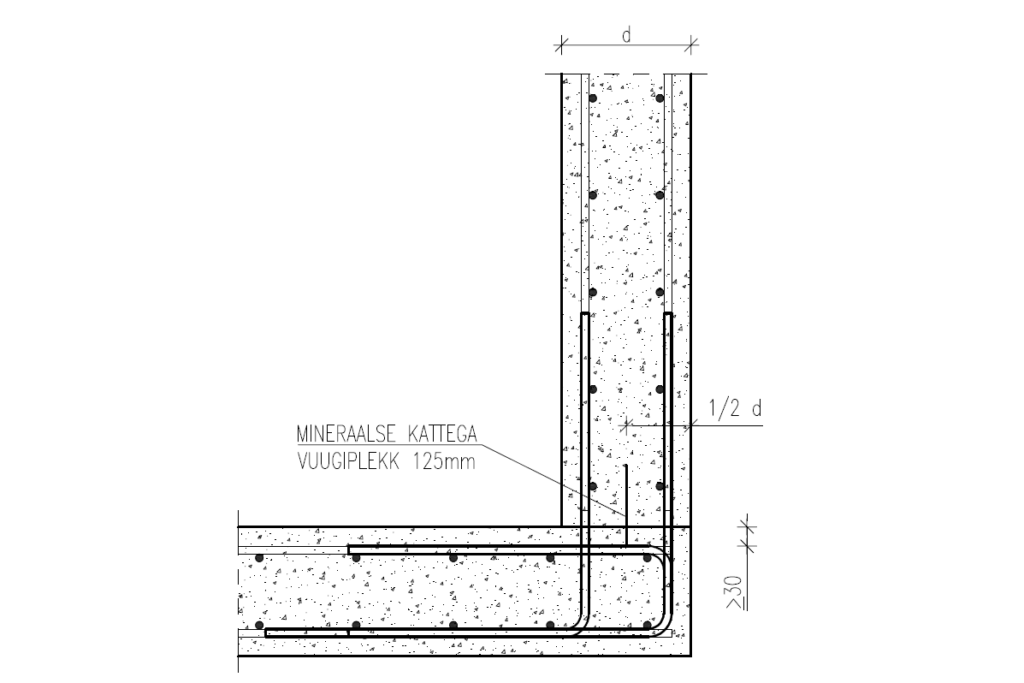

The picture shows how the joint profile WPM Sealing Element 125L BIT (custom-made product) remains in the tile foundation, making the joint between the tile foundation and the wall waterproof.

Crystalline admixture

The constant challenge for the construction industry is to do more in less time and at a lower cost.

The most significant pressure on prices in Estonia was during the previous crisis in 2009-2010 when builders wanted new, lower-priced solutions.

We met the market’s demands by replacing the “classic” bituminous or artificial materials-based waterproofing materials with a crystalline admixture which is added to the concrete mix at the factory. Since 2009, we have been offering a complete waterproofing solution with crystalline additive and other products in this system, including construction and deformation joint profiles, on large construction sites.

In this way, we have offered a complete waterproofing solution for underground, reinforced concrete structures at least half cheaper than before.

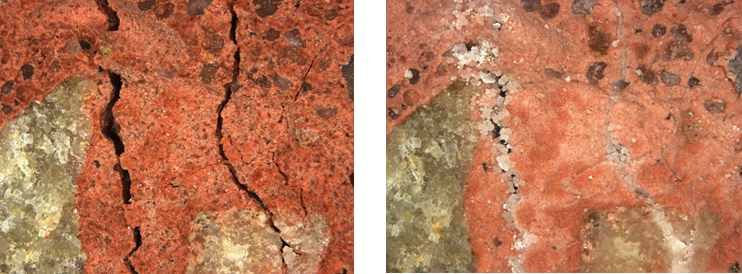

The crystalline admixture gives the concrete a “self-healing” ability. Together with the water entering the crack, the admixture can close the static cracks in the concrete with an opening width of less than 0.4 mm.

Picture 1: Concrete before and after contact with water (~ 14 days). Waterproofing of concrete structures with crystalline admixture.

When the gap is under constant dynamic load, i.e., moving constantly, the admixture that increases the water resistance on the concrete cannot fill cracks with an opening greater than 0.4mm.

Construction joint profiles

When engineers calculate 0.2… 0.3mm shrinkage to the reinforced concrete structure in the construction design, then, in reality, it may still happen that the resulting cracks open more than 0.4 mm and do not grow together.

While working on various projects, we saw that non-watertight cracks still appeared on occasion. Therefore, a working solution had to be found. In 2018, we started the production of various watertight profiles in Estonia with WPMEstonia OÜ, which enabled us to solve the problem described above.

Our product range includes waterproof sheet metal profiles installed in joints, either in roll or sheet profile. Secondly, we offer watertight mesh and sheet metal Stop-End profiles for slab foundation joints.

We have also created a solution for controlling the shrinkage of reinforced concrete structures so that the crack is immediately waterproof at the desired location. The solution is the WPM Crack Inducer profile. This profile is designed so that the resulting crack is pin-shaped in the cross-section of the structure. The pin-shaped crack does not reduce the strength of the structure significantly, in which case we can create such a crack in the load-bearing structures.

Gif 1

Gif 1: WPM Crack Inducer pin-shaped crack that is instantly waterproof. Waterproofing solution with joint profiles and crystalline additive.

We use the WPM Crack Inducer profile with a fixed step according to the reinforcement in the structure and the thickness of the structure.

Paavo Pikandi, the designer of the CIVEN design bureau, and Indrek Uusalu, the head of WPMEstonia and Primostar, talk about how to control the shrinkage of concrete.