ABOUT COMPANY

For over 25 years, Primostar has been helping builders create watertight and long-lasting structures with complete waterproofing and construction material solutions – from foundations to roofs.

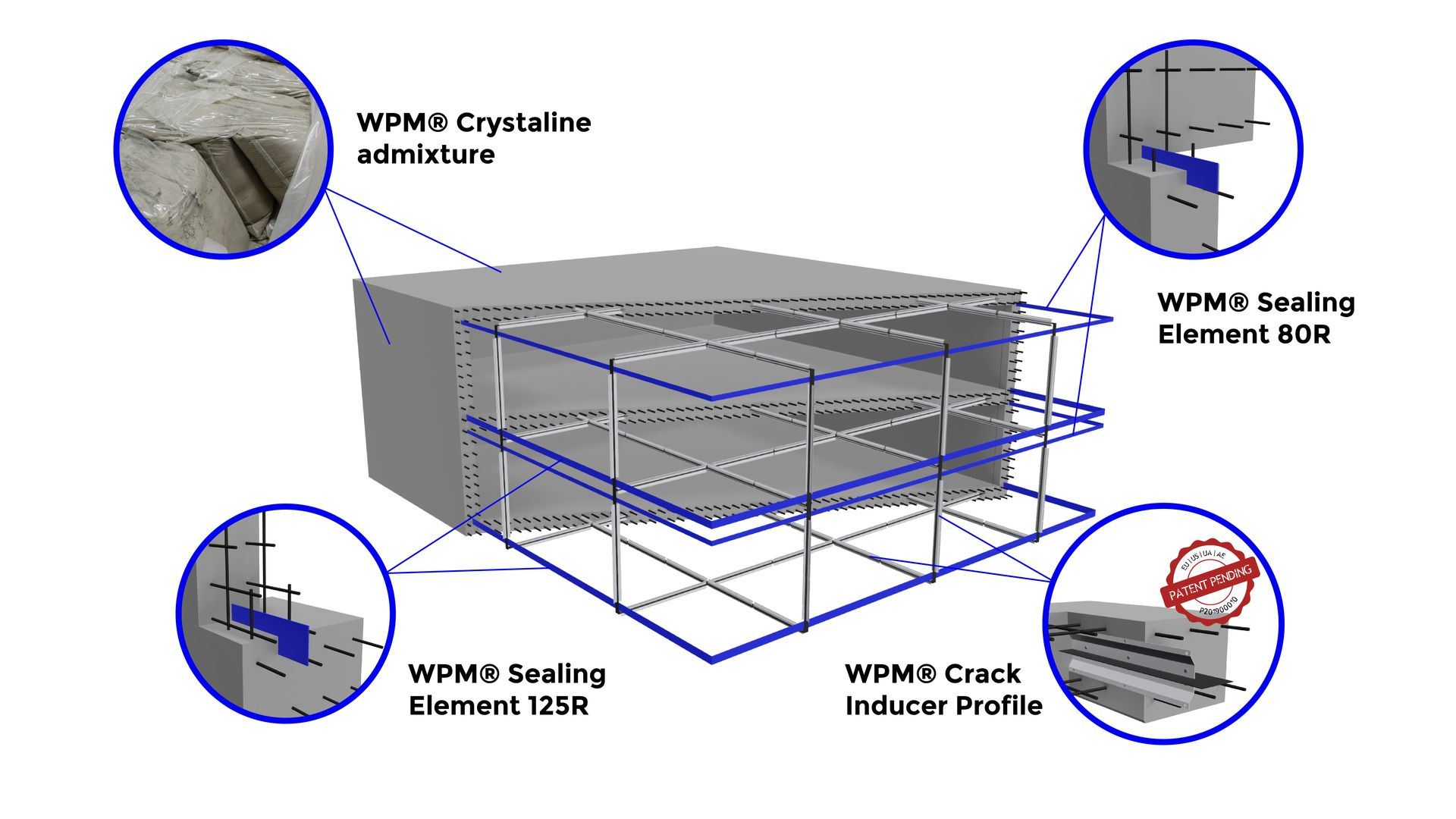

At the heart of our work is the membrane-free “white tank” system – an environmentally friendly solution that makes concrete watertight from within. One of its key components is patented in three countries, reducing material use by up to eight times – a smarter, greener, more sustainable way to build.

Most of our materials are of German quality and come with professional consultation and installation guidance, ensuring reliability, precision, and long-lasting performance.

Trusted by contractors, developers, architects, and construction professionals, Primostar guarantees durable, watertight, and energy-efficient structures that last for decades.

Innovation

- Proven innovations that keep your structures safe for generations.

- Smart opportunities that make your construction faster, more versatile, and cost-effective.

- Smart, forward-thinking choices that save you time and money.

Reliability

- A partner you can rely on: listening, adapting, and solving challenges with you.

- An open-minded and reliable partner who listens to your needs, adapts to every situation.

- Flexible, personal solutions tailored to your situation and challenges.

Sustainability

- Environmentally friendly opportunities that make your project safer, smarter, and future-proof.

- Sustainable solutions with recyclable materials — helping you build responsibly without compromising quality.

- The right solution for your needs — reliable quality and long-lasting peace of mind.

Mission

To offer environmentally friendly and sustainable waterproofing solutions.

Vision

We want to be the leading company developing and offering waterproofing solutions in the entire Baltic and Scandinavia

years of operation

in a different market

completed projects with

White Tank solution

Primostar OÜ history

What is the story behind the development of Primostar's eco-friendly waterproofing solution?

In the past, we imported construction joint profiles from German manufacturers for many years, but when using them on the construction site, the products developed some defects, which we wanted to improve with our own production. That's how the idea came to create the WPM® brand in 2018, whose main field of activity was waterproofing solutions for construction joints and controlled volume shrinkage cracks in concrete structures.

WPM® - from idea to implementation

We started production with simpler R and L construction profiles, which would be weather-resistant and become homogeneous when solidified with concrete.

In the first half of 2019, we started patenting the Crack Inducing Waterstop profile, and at the end of the year, the profile was used for the first time on the project Valge Street 16, as you can see in the video below.

Primostar's integral, i.e., white tank waterproofing solution, is a comprehensive approach to underground, reinforced concrete structures - using WPM® Metal Sheet waterstop, Crack Inducing waterstops, and crystalline waterproofing concrete admixture.

8 920+

Crack Inducing Waterstop

amount (in meters)

83 691+

Metal sheet Waterstop amount

(in meters)

488 969+

Crystalline waterproofing admixture amount (kg)

WPM® Crack Inducing Waterstop

is used to control shrinkage cracks, which results in the planned shrinkage crack being immediately waterproof and in the desired location.

WPM® Metal Sheet Waterstop

used for waterproofing construction joints against pressurized water in various underground reinforced concrete constructions.

Crystalline waterproofing admixture

gives the concrete a self-healing ability. Together with the water entering the crack, the admixture can close the static cracks in the concrete with an opening width of less than 0.4 mm.

Need more information about the white tank solution?

PASSIONATE TO WATERPROOF

BELOW GRADE SMARTER AND GREENER!

SAVE

THE ENVIRONMENT

- You will use 10X less waterproofing material.

- In order to be environmentally friendly, we have removed the packaging from the products.

SAVE

TIME

- Compared to conventional waterproofing, the installation of white tank waterproofing is up to 20x faster.

- The solution will last as long as the construction.

SAVE

RESOURCE

- You save on labor costs because the installation can be done by any concrete worker.

- Installation does not require additional equipment or special technology.

Read more about the environmentally friendly system of white tank:

Some examples of completed works

TalTech dormitory at

Akateemia tee 7 and 9.

Köster KSK was used for the first time.

Roll waterproofing volume 9500 m2.

Eesti Energia oil factory

Crystalline waterproofing admixture project.

Volume of concrete admixture 1714 m3.

Tondiraba Ice hall

Primostar supplied the material for the waterproofing of the Tondiraba ice hall: a pre-installed membrane under the floor, cold adhesive KSK on the walls, and the whole structure was cast with a crystalline admixture.

Volume of concrete admixture 6500 m3.

Roll waterproofing volume 15,000 m2.

Viimsi Primary School

Roll waterproofing volume 1778 m2.

Tartu mnt 52

Waterproofing and TPO roofs.

Volume of concrete admixture 1420 m3.

Roll waterproofing volume 1547 m2.

Veho car center

The volume of roll waterproofing is 3549 m2.

Indrek Uusalu joined Primostar.

Indrek Uusalu joined Primostar.

Supplying projects with crystalline waterproofing admicture and metal-sheet waterstops.

Supplying projects with crystalline waterproofing admicture and metal-sheet waterstops.

The first

The first