PASSIONATE TO WATERPROOF UNDERGROUND STRUCTURES SMARTER AND GREENER!

SAVE

ENVIRONMENT

- You will use 10X less waterproofing material.

- In order to be environmentally friendly, we have removed the packaging from the products.

SAVE

TIME

- Compared to conventional waterproofing, the installation of white tank waterproofing is up to 20X faster.

- The solution will last as long as the structure.

SAVE

RESOURCES

- You save on labor costs because the installation can be done by any concrete company while installing rebars.

- Installation does not require additional equipment or special technology.

Environmental sustainability is an increasing trend throughout the world. Cheaper, more efficient, and also more environmentally friendly solutions are being sought. Although today the experience of using environmentally friendly solutions may not yet be a market advantage, we are approaching a time when companies with the longest experience of environmentally and resource-efficient solutions inevitably become the leaders in the industry.

Both end consumers and contractors are becoming more and more environmentally aware, and so the demand for environmentally friendly construction materials will surely increase over time.

Primostar offers a more sustainable solution for below-grade concrete structure waterproofing that has already proven itself in the Estonian market for over 10 years. The water resistance of concrete structures is achieved by using different weather-resistant, operation costs saving methods that also prolong the life of concrete buildings.

As more and more new buildings are being built underground due to the lack of space on the ground, especially in the cities, it is important to choose to waterproof wisely. As there are more waterproofing solutions than ever before, it is necessary and wise to choose the most optimal solution for the structure and its purpose and stop overspending.

The trend of the new era of waterproofing is integral, i.e., white tank waterproofing with crystalline waterproofing admixture, which is used to introduce active healing crystals into the concrete before pouring.

Over the last 10 years, the construction sector in Europe has changed so much that it is moving from bitumen-based products to the more environmentally friendly crystalline waterproofing admixture. The crystalline admixture provides both time and financial savings and is also environmentally friendly thanks to natural components, not an oil-based artificial material such as bitumen that emits many toxic compounds into the environment.

In addition, the use of bitumen is also directly harmful to human health, posing a genotoxic risk. Fortunately, we can also see that the currently common bitumen solutions are also about to change. New and more environmentally friendly solutions have been and are to be launched in the future.

Primostar is aware of world innovations and is the right partner for any contractor and reseller who wishes to keep up with trends in the construction sector.

Our main focus in waterproofing is to utilize materials smartly and achieve maximum results. This would lead us to use fewer materials and, as a result, pollute our environment much less.

What is the Environmental Impact of Using the White Tank Method?

RAW MATERIAL

Galvanized steel sheet - a long lasting and durable metal, where steel dipped in a zinc bath multiplies its life. And at the end of the life of the same material, it is possible to recycle it.

Mineral coating - contains environmentally friendly natural components.

Crystalline admixture - the main components are compounds that are very common in nature.RAW MATERIAL QUANTITY

Material usage, compared to classical membrane waterproofing

is 2-8 times less

.

(calculations are below)

DURATION

as long as the structure.

INSTALLATION COSTS

(calculations are below)

PACKAGING

TRANSPORT

LABOR COSTS

White Tank Waterproofing Materials

WPM® Metal-sheet

Waterstops

To watertight construction joints against pressurized water in underground, reinforced concrete structures.

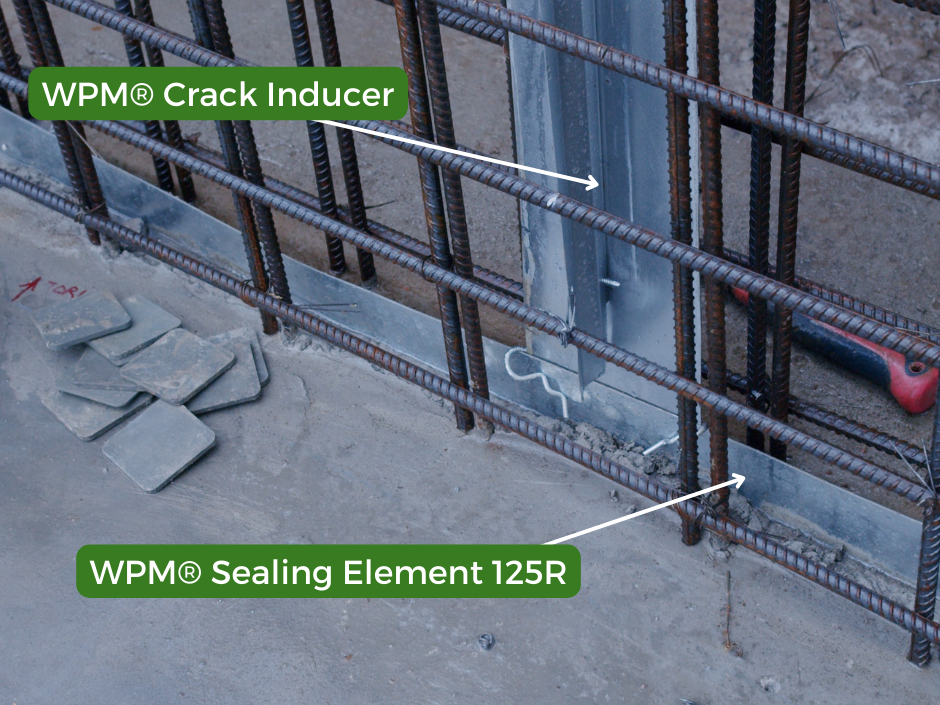

WPM® Crack Inducing Waterstop

To control and watertight concrete shrinkage cracks, which results in the planned shrinkage crack being immediately waterproof and located in the desired location.

Crystalline Waterproofing Admixture

To waterproof concrete. Together with the water entering the crack, the admixture can close the static cracks in the concrete with an opening width of less than 0.4 mm.

WATERPROOFING CALCULATIONS

Labor and material costs

walls

245m²

floor

1000m²

Sample project

1245m²

Integral, i.e., White Tank Waterproofing

The material consumption of WPM® metal-sheet waterstop 125R per m² is 0.57kg/m and WPM® 80R – 0.32kg/m.

WPM® Crack Inducer(20/60/20) material consumption is 1.11+0.4= 1.51kg/m.

The average consumption of the crystalline additive is 1m³= 1kg

Until the end of the structure's life.

Installation time

1-2 days

Material consumption

0,48kg/ 1m², makes a total of 597 kg.

Classical Membrane

Waterproofing

The thickness of SBS bitumen roll material is between 2-5 mm.

The overlap should be 5-10 cm.

The weight is between 3.5 and 5 kg/m².

Lifetime

25 years

Installation time

15-20 days

Material consumption

9,7kg/ 1m², makes a total of 12 076 kg.

Which Waterproofing Solution Should You Choose

for The Project?

The constant challenge in the construction sector is to do more with less time and less cost. This means that contractors responsible for waterproofing processes must also find new ways to maximize the result of working hours and minimize their time doing the work. It makes sense to look toward environmental sustainability and labor cost savings. Both payroll funds and material costs will keep simultaneously increasing. It is, therefore, necessary to find ways in which work can be carried out in a better and more sustainable way.

The goal is always to choose the most optimal solution, which would also be environmentally friendly and help save resources.

From the above calculations, we can conclude that in terms of material consumption, the white tank solution is 10x more economical, and the difference in installation time is as much as 20X compared to classical membrane waterproofing. In addition, there is a 4-fold difference in the lifespan of the waterproofing, which means that the classic waterproofing must be renewed at least 4X during its time compared to the white tank waterproofing solution.

In summary, it is necessary to proceed from the structure and its purpose of use and remember that all waterproofing solutions complement each other. It is important to take into account the location of the object and what conditions the waterproofing must meet.

Want to waterproof environmentally friendly and long-lasting way?