Elevator pits are the deepest parts of a building, and it is crucial to ensure their water tightness. Water tends to reach the elevator pit quickly, and since elevators are connected to electricity, it is essential to minimize the risk by guaranteeing complete water tightness.

The elevator pit is typically one of the first structures cast on-site during construction. To reduce risks, it is recommended to construct the elevator pit using waterproof concrete. However, transporting a half-empty concrete mixer truck to the construction site can take time and effort. This often leads to the elevator pits being built from various blocks, which are tricky and challenging to waterproof. Unfortunately, the leaking issues often become apparent only after the pit is completed, making it difficult to fix.

SOLUTION

At Primostar, we have recognized this problem and taken steps to address it. We offer a solution in the form of precast watertight elevator pit elements, which simplify the process. These elements can be easily lifted into place, saving you time on the construction site and the hassle of ensuring water tightness.

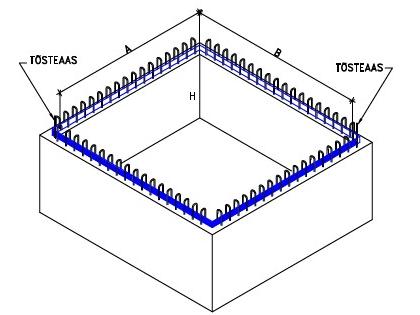

The WPM® elevator pit element is a watertight precast, monolithic concrete product assembled in Estonia. Concrete water tightness is achieved with a crystalline waterproofing admixture in the concrete. The watertight precast element consists of bottom and side walls, anchors, and a WPM® Sealing Element 125R that has been installed on the upper edge of the side wall to ensure that the construction joint between the elevator pit and the floor slab is watertight.

Advantages of a watertight precast elevator pit

- Considerably easier and faster installation

- The reliability of waterproofing does not depend on on-site labor or weather conditions

- A ready-made watertight element ensures a leak-free elevator pit

- Anchors for convenient connection to the next structure

- Element from monolithic concrete without construction joints

- Officially tested at TalTech – test no N° 389/23

- The tested water penetration under maximum pressure (500±50 kPa) is up to 14 mm.

Additionally, we can also provide similar elements for underground pump sumps. If you are interested or have any questions, don't hesitate to contact us.